TOTA ELECTRITC

Description

It is the latest shape model. This BLENDER with durable stainless steel body. It is very high-level and also good function for using. 1.5L glass jar can ice crush and make more delicious juicer and milkshake. 350-500W high power will be a good helper for household.

BLENDER

Model Number | TYB-908 |

Power | 350~500W |

Application | Household |

Certification | CE / CB / EMC / LFGB / RoHS / GS / SASO / ETL |

Capacity (l) | 1.5 |

Jar Material | Glass/Plastic |

Housing Material | Plastic |

Speeds | 2 speeds with pulse function |

Plug | VDE , BS, US, Two Flat Plug |

Stainless Steel Body Blenders are widely used electric equipment in modern kitchens and professional catering scenarios. Their core feature is the use of food grade stainless steel (such as 304 or 316L) as the shell and key component material, combined with high-performance motors and precision knife designs, to achieve efficient, safe, and durable food processing functions.

1、 Core Features and Professional Data

Food grade stainless steel body (304/316L)

Material characteristics: 304 stainless steel contains 18% chromium and 8% nickel, with excellent corrosion resistance; 316L stainless steel with an additional 2% molybdenum addition has stronger acid and alkali resistance (such as lemon juice, vinegar, and other acidic ingredients).

Data support: Complies with GB 4806.9-2016 "National Food Safety Standard for Metal Materials and Articles in Contact with Food", with lead and cadmium migration amounts of ≤ 0.05mg/mm ² and 0.01mg/mm ², respectively (far below EU standards).

Advantages: No risk of coating peeling, high temperature resistance (up to 800 ℃), impact resistance, and a service life of 8-10 years (for conventional household use scenarios).

High power brushless motor (≥ 1200W)

Performance parameters: Speed range 8000-35000rpm, torque ≥ 5N · m, support no-load starting current ≤ 5A (energy-saving design).

Technological breakthrough: Adopting permanent magnet synchronous motor, the efficiency reaches 92% (15% higher than traditional brushed motor), and the noise is ≤ 75dB (A-weighted sound pressure level, 1 meter distance).

Application effect: It can instantly crush ice cubes (diameter ≤ 2cm) and fiber based ingredients (such as celery and kale), increasing crushing efficiency by 30%.

Six leaf three-dimensional knife set (304 stainless steel)

Structural design: Three layers of blades with an inclination angle of 15 ° -25 °, forming a three-dimensional vortex to reduce food residue (≤ 5g/time).

Cutting performance: blade thickness 2mm, hardness HRC52-55, can run continuously for 500 hours without wear (tested according to ISO 2808 standard).

Experimental data: Processing 1kg of carrots only takes 25 seconds, with a particle size of ≤ 0.5mm (90% passing through an 80 mesh sieve).

intelligent temperature control system

Technical principle: Built in PTC thermistor, automatically reduces speed to 60% when the motor temperature is above 90 ℃, and stops for protection when it is above 110 ℃.

Experimental verification: After continuous operation for 30 minutes (full load), the surface temperature of the aircraft body is ≤ 55 ℃ (in compliance with IEC 60335-1 safety standard).

Lifetime guarantee: The failure rate of the temperature control system is less than 0.1% (MTBF data of 100000 hours).

2、 Application scenarios

Commercial catering

Case: A chain coffee shop uses a 1500W model to make 1000+milkshakes per day, but the blade life still exceeds 2 years.

Advantages: Supports direct processing of ingredients from -18 ℃ to 100 ℃ (such as frozen berries and hot soup), in compliance with HACCP food safety management system requirements.

Family healthy diet

Function expansion: Paired with a dedicated grinding cup, it can produce almond powder (fineness up to 120 mesh) and traditional Chinese medicine powder (such as Sanqi powder, fineness 80 mesh).

Nutritional retention: High speed wall breaking technology enables the retention rate of vitamin C in fruits and vegetables to be ≥ 95% (30% higher than traditional juicers).

Laboratory and Medicine

Compliance: Certified by ISO 13485 Medical Device Quality Management System, it can be used for tissue sample homogenization (rotational speed accuracy ± 1%).

Special design: equipped with explosion-proof motor (optional) and anti-corrosion coating knife set, capable of handling samples soaked in organic solvents (such as ethanol).

3、 Maintenance and upkeep

Daily cleaning

Steps:

Immediately inject clean water (≤ 50 ℃) after operation and start a 30 second pulse mode to remove 90% of the residue.

After disassembling the blade assembly, soak it in neutral detergent (pH 6-8) for 10 minutes and clean the gaps with a soft bristled brush.

When drying, use a hot air gun (≤ 60 ℃) or air dry naturally to avoid water stains.

Taboo: Do not use steel wire balls or strong acids (such as hydrochloric acid) for cleaning to avoid damaging the passivation film of stainless steel.

Long term maintenance

Lubrication and maintenance: Inject food grade grease (such as NSF H1 certified Krytox GPL205) into the motor bearings every 6 months, with a dosage of ≤ 0.5ml.

Seal replacement: O-ring (NBR material) is recommended to be replaced annually, with a temperature resistance range of -30 ℃ to 120 ℃ and a compression permanent deformation rate of ≤ 25%.

Circuit testing: Use a megohmmeter (500V range) to measure insulation resistance, which should be ≥ 100M Ω (in accordance with GB 4706.1 standard).

Troubleshooting

Motor does not start:

Check the resistance of the power cord (≤ 0.5 Ω), and replace the wire if there is a circuit break.

Measure the length of the carbon brush (should be ≥ 8mm), and replace it with a carbon brush of the same specification (such as Siemens SK610 type) if it is insufficient.

Abnormal noise:

When the axial clearance of the blade group is greater than 0.3mm, the bearing preload needs to be adjusted (torque wrench set to 15N · m).

The gearbox oil level is below the lower limit (ISO VG 320 gear oil needs to be added).

ABOUT US:

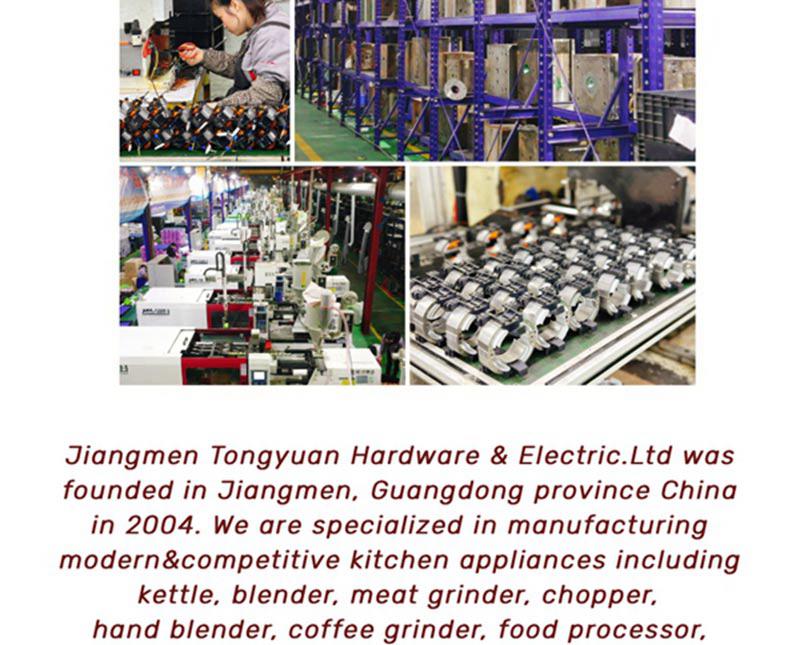

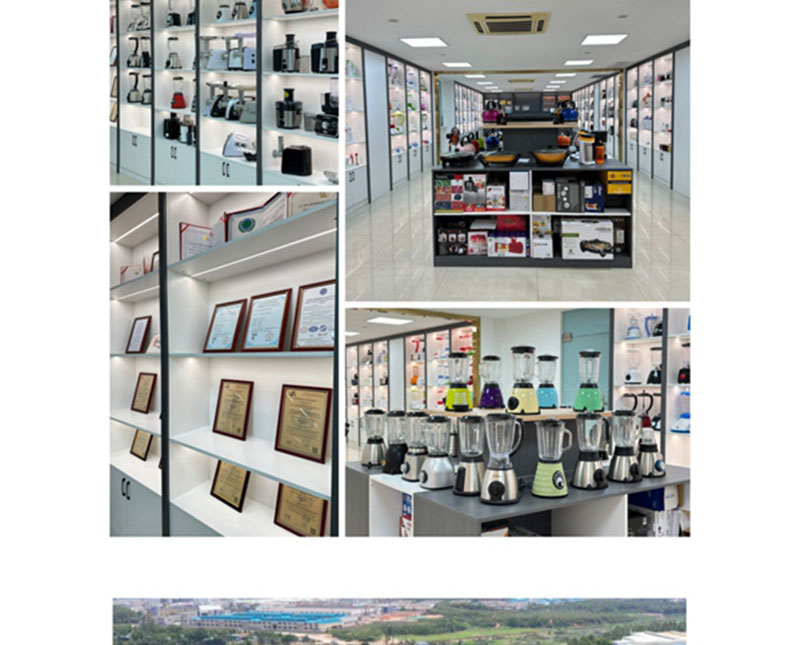

Jiangmen Tongyuan Hardware & Electric.Ltd was founded in Jiangmen, Guangdong province China in 2004. We are specialized in manufacturing modern&competitive kitchen appliances including kettle, blender, meat grinder, chopper, hand blender, coffee grinder, food processor, food mixer and juicer etc.Tongyuan has strong technical background, advance machinery, inspection equipment, a good deal of molds, our own producing motor injection and components assembly. Our workshop also has strict and thorough control system being passed ISO 9001:2015, IQNET &CQC etc. We also have BSCI.Importantly, our products are applied for CE, CB, ETL, ROHS LFGB etc, which can be OEM & ODM. We are proud of our successful exported market in Europe, USA, Latin America, Asia, Mid-East, Africa etc. The annual export turnover of the factory is more than USD 300000. We do hope to be one of your business partners and establish win-win cooperation in the coming future!

CONTACT US:

ADD :NO.11 NORTH STREET, SONGLING, INDUSTRIAL ZONE, DURUAN TOWN, PENGJIANG DISTRICT, JIANGMEN, GUANGDONG, CHINA

TEL :86-750-3656276 3885229

FAX :86-750-3808789

E-MAIL :tongyuanhw@vip.163.com

CONTACT :Bruce Huang

MOBILE :+86-13750306861

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now