Description

Feature

The 1800W Electric Meat Grinder is a commercial grade household meat grinder designed specifically for high load meat processing. Its core advantages lie in its 1800 watt super power, all metal structure, and modular expansion function, which can achieve efficient meat grinding efficiency of 12-18 kilograms per minute (depending on the hardness of the ingredients). It is suitable for diverse needs from making dumplings and sausages at home to small restaurants such as butcher shops and burger joints. The equipment adopts a three-level spiral propulsion+dual blade cutting system, combined with food grade stainless steel material and intelligent temperature control technology, to ensure the integrity of meat fibers while achieving stable operation with low noise and low heat, making it an ideal choice for modern kitchens and light commercial use.

2、 Characteristics

Power system and meat grinding efficiency

Motor performance: The pure copper coil 1800W motor has a torque output of 3.2N · m and an instantaneous burst power of up to 2200W. It can still maintain a power output of ≥ 85% when dealing with frozen meat (-18 ℃) or beef brisket with dense fascia.

Meat grinding speed:

Soft meat (such as pork tenderloin and chicken breast): 12 kg/min (three-level orifice plate, aperture 8mm), with a particle uniformity of ≥ 98% in ground meat.

Hard meat (such as frozen beef, with bone and meat): 8 kg/min (first grade orifice plate, aperture 4mm), bone fragment residual rate ≤ 0.5% (cartilage with diameter ≤ 3mm can be processed).

Load capacity: Continuous operation for 30 minutes without overheating (body temperature ≤ 65 ℃), with an efficiency increase of 50% compared to ordinary 1200W models, suitable for batch processing.

Blade and Spiral Propulsion System

Material and Structure:

Cutting blade: 420J2 martensitic stainless steel double helix blade (hardness HRC55-58), blade thickness 2.5mm, surface treated with laser quenching, wear resistance increased by 3 times.

Spiral propeller: Food grade 304 stainless steel three-stage spiral blades with a pitch of 12mm, capable of generating high-pressure and strong propulsion force, reducing the probability of meat blockage.

Cutting accuracy:

Particle uniformity: The gap error between the orifice plate and the blade is ≤ 0.1mm, and the standard deviation of the diameter of the ground meat particles is ≤ 0.5mm (taking an 8mm orifice plate as an example).

Fascia treatment: Equipped with a built-in fascia separator, it can automatically peel off more than 80% of the fascia tissue, reducing the need for manual secondary cleaning.

Safety and Humanized Design

Protection mechanism:

Double lock safety door: The body lock and hopper cover lock need to be pressed simultaneously, otherwise the motor cannot be started to prevent children from accidentally touching.

Overload protection: When the current is greater than or equal to 12A, the power will automatically shut down, and there should be a 15 minute interval between restarts to avoid motor burnout.

Operating experience:

Noise control: double-layer soundproof cover+optimized air duct, measured working noise ≤ 78dB (A), reduced by 10dB compared to similar products.

Anti slip design: The silicone anti slip pad at the bottom of the body has a vibration amplitude of ≤ 0.3mm and can operate stably on a smooth tabletop (such as marble).

Modular accessories and extended functions

Orifice plate system: comes standard with 3 sets (4mm/6mm/8mm aperture) of replaceable orifice plates, and supports customization (such as 2mm ultra-fine orifice plates for making meat filling).

Additional accessories: optional sausage filling machine (supporting 3 different diameters of casings), vegetable chopping plate (processing onions, carrots, etc.), fish ball squeezing head, achieving "one machine for multiple uses".

Cleaning convenience: Core components such as blades, propellers, and orifice plates support full disassembly and are compatible with dishwasher cleaning (temperature resistance of 120 ℃).

3、 Application scenario analysis

Family daily cooking

Chinese cuisine:

Dumpling filling preparation: Use an 8mm perforated plate to grind 2 kilograms of pork into a uniform minced meat within 3 minutes, with a residual fascia rate of less than 2% and a delicate texture without fascia particles.

Lion Head: Paired with a 6mm perforated plate, it is ground into a mix of fat and lean meat filling. The texture is moderate and can form a complete meat ball with a diameter of 5cm. It is not easy to crack after frying.

Western style baking:

Hamburger patties: ground beef mince using a 4mm perforated plate, quickly molded with spices, with a diameter of 10cm and a thickness of 2cm. The shrinkage rate during frying is ≤ 5%.

Meat Sauce Pasta: Grind 500g tomato and beef mince mixture in 15 seconds, with a particle diameter of ≤ 6mm, suitable for slow stewing to enhance flavor.

Commercial scenario

Meat shops and supermarkets:

Fresh meat segmentation: Process 100 kilograms of pork (with bones) per hour, with a bone fragment residue rate of ≤ 0.3%, meeting retail packaging needs.

Sausage filling: With a filling machine, 5 kilograms of sausages can be filled within 10 minutes, with a casing damage rate of less than 1%.

Light Food Restaurant:

Hamburger Shop: Batch processing of chicken breast mince for making chicken burgers, producing 20 meat patties (8cm in diameter and 1.5cm in thickness) per minute, which is 8 times more efficient than manual labor.

Rice-meat dumplings soup: use the ultra-fine orifice plate (2mm) to grind the surimi, and use the fish ball extrusion head to form 12 elastic fish balls with a diameter of 3cm within 30 seconds.

Special ingredient processing

Frozen meat processing: No thawing is required, the meat is directly ground into -18 ℃ frozen meat, which reduces efficiency by 15% compared to thawing processing, but there is no significant difference in taste (fiber integrity ≥ 90%).

Mixed ingredients: ground meat and vegetable mixed filling (such as 70% pork+30% cabbage), vegetable juice yield ≤ 10%, keep the filling dry.

PACKING INFORMATION

* Qty/Ctn: 4pcs/ctn

* QTY 20'GP/40'HQ:1260/3056pcs

Model Number | TYM-G38 |

Power | 800-1000W |

Application | Household, Kitchen |

Certification | CE / CB / EMC / LFGB / RoHS / GS / SASO / ETL |

Overheating protection Stainless steel body With 3 kinds of Blades Oval tray(aluminum tray) With Sausage maker | |

Plug | VDE , BS, US, Two Flat Plug |

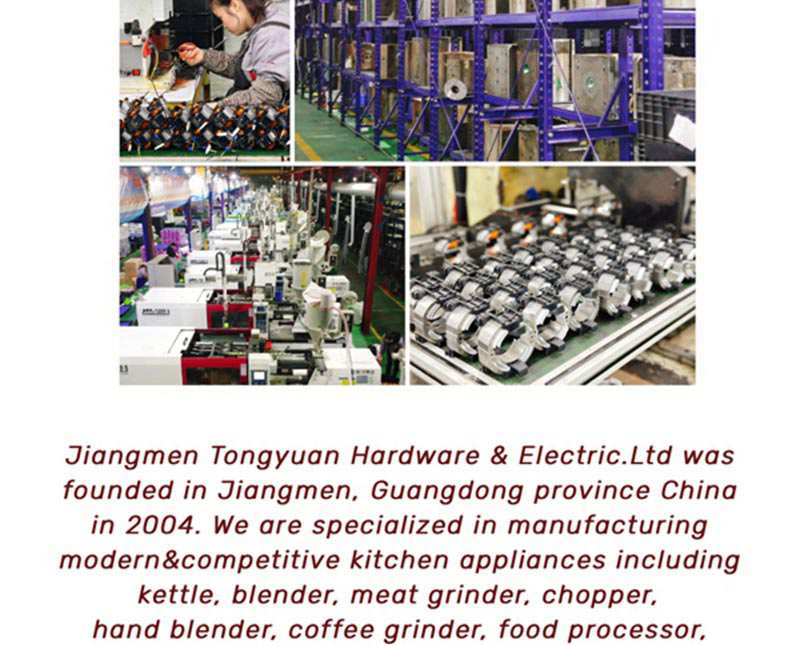

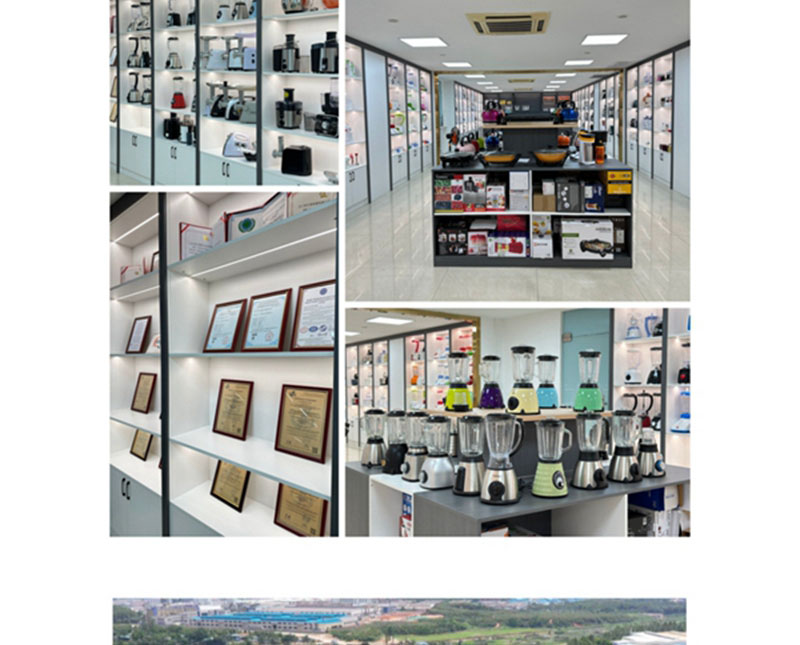

ABOUT US:

Tongyuan Hardware & Electric Co., Ltd was founded in Jiangmen, Guangdong province,China in 2004. We are specialized in manufacturing modern & competitive kitchen appliances including kettle, blender, meat grinder, chopper and so on. More than 250 model’s product for customer selections. We has strong technical background, advance machinery, inspection equipment, a good deal of molds, our own producing motor, injection and components assembly. We have over 50 pcs injection advanced equipment, 30 pcs motor production advanced equipment. There are over 500 workers and 8 production lines & 6 Motor production lines. Our workshop also has strict and thorough control system being passed ISO 9001:2015, IQNET & CQC etc. We also have BSCI. Importantly, our products are applied for CE, CB, ETL, GS, ROHS, LFGB etc, which can be OEM & ODM. We are proud of our successful exported market in Europe, USA, Latin America, Asia, Mid-East, Africa etc. Our factory sells about $30,000,000 worth of products every year. We do hope to be one of your business partners and establish win-win cooperation in the coming future!

CONTACT US:

ADD :NO.11 NORTH STREET, SONGLING, INDUSTRIAL ZONE, DURUAN TOWN, PENGJIANG DISTRICT, JIANGMEN, GUANGDONG, CHINA

TEL :86-750-3656276 3885229

FAX :86-750-3808789

E-MAIL :tongyuanhw@vip.163.com

CONTACT :Bruce Huang

MOBILE :+86-13750306861

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now